PRODUCT DETAIL

REAGENT PREPARATION AND STORAGE INSTRUCTIONS

The test cassette should be stored at 2-30℃ inthe sealed pouch. Avoid humidity, heat anddirect sunlight. The test cassette is stablethrough the expiration date printed on thesealed pouch.DO NOT FREEZE.

SPECIMEN COLLECTION AND STORAGE

1. Centrifuge whole blood to get plasma orserum specimen.

2. If serum is not tested immediately, it shouldbe refrigerated at 2-8°C. For storage periodgreater than three days,freezing is recom-mended. Such specimen should be broughtand equilibrated to room temperature(15-30°C) prior to use.

ASSAY PROCEDURE

1. Bring the pouched test cassette to room tem-perature (15-30 ℃) prior to testing. Do not openthe pouch until ready to begin testing.

2. Remove the cassette from the sealed pouch.Lay it on a flat, clean and dry surface.

3. Using the provided pipette, add one drop offresh specimen to the sample well.

4. Hold the buffer bottle vertically and add 1 dropto the sample well. lf using a pipette, change anew one to avoid cross-contamination.Drawand transfer 2-3 drops of buffer to the samplewell.

5.Read the result between 15-20minutes.Donot read results after 20 minutes.

5.Read the result between 15-20minutes.Donot read results after 20 minutes.

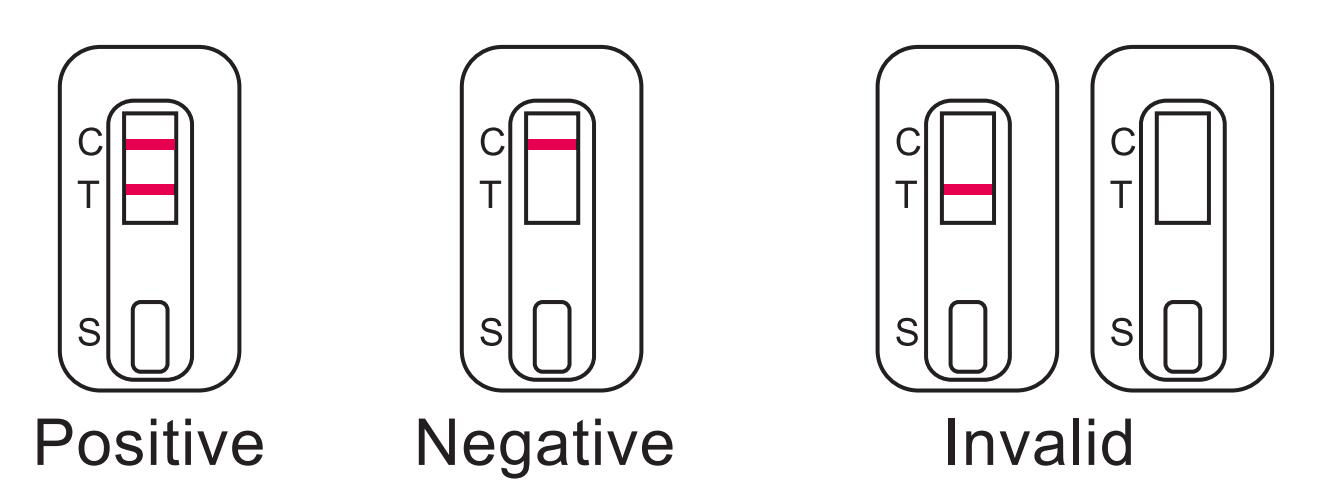

INTERPRETATION OF RESULTS

POSITIVE: Two pink lines appear in the resultwindow, one in the control region and anotherone in the test region. This indicates a positiveresult and H. Pylori antibody having been detected.

NEGATIVE: Only one pink line appears in thecontrol region (C). This indicates a negativeresult and H. Pylori antibody having not been detected.

INVALID: If the control line fails to appear, the test results are invalid regardless of the presence or absence of the test line.

NEGATIVE: Only one pink line appears in thecontrol region (C). This indicates a negativeresult and H. Pylori antibody having not been detected.

INVALID: If the control line fails to appear, the test results are invalid regardless of the presence or absence of the test line.

NOTE: Insufficient specimen volumeorincorrect procedural techniques are the mostlikely reasons for the control line failure.Review the procedure and repeat the test witha new cassette. lf problem persists,please contact your local distributor.